In the aluminum alloy die-casting production process, temperature is one of the core process elements. The quality of die-casting mold temperature control directly affects product quality and production efficiency. The choice of die-casting mold temperature control method is particularly important.

The importance of die-casting mold temperature

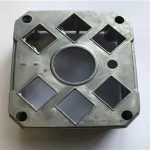

die casting mold is the molding process equipment in the casting production process. Whether the temperature field distribution established in the mold is stable or not has an important impact on the quality of castings, production efficiency and mold service life, and is directly related to the cost and economic benefits of casting production. The temperature field in the mold must be within the range of process requirements, so that castings with qualified appearance and internal quality can be obtained. On the contrary, if the temperature is too high, defects such as strains and bubbles will be formed, which will extend the cooling time and reduce production efficiency; if the temperature is too low, it will Defects such as cold barrier, insufficient pouring, and pores. Die-casting molds are produced under high temperature and high pressure environment for a long time. If the mold temperature field is unstable, long-term periodic thermal expansion and contraction, the mold is more prone to failure, greatly shortening the service life and reducing production efficiency.

Die-casting mold temperature control principle

During the casting process, the heat exchange between the mold and the molten metal achieves an ideal heat balance, that is, the mold absorbs heat and discharges heat equal to achieve dynamic heat balance. After the process is selected, the mold temperature reaches the working temperature range of the casting, which is easy to form hot spots. Locally perform spot cooling to promote the formation of heat balance.

Hot festival

- Location: The casting structure has the highest temperature during the die-casting process, and it is easy to form shrinkage holes, shrinkage porosity and stress concentration locations during the cooling process.

- Control method—point coolerIn order to achieve the purpose of saving water, the point cooler adopts the method of water recycling. In order to ensure sufficient pressure, a collection and distribution box is added.

- Increase the high-pressure point cooling in the core at the hot section of the die casting.

- Point cold water treatment: Point cold water in the cooling pipeline will encounter sudden cooling, sudden heat, small pipelines, etc. The old water treatment generally uses softening treatment, which often fails to meet the water quality requirements in production. Frequent blockages cause huge loss of manpower, material resources, and financial resources. RO reverse osmosis water treatment devices are generally used to process the cold water into pure water.

Heat balance

- (1) Principle: During the die-casting production process, the heat absorbed by the mold must be the same as the heat discharged, so as to prevent the mold from getting colder or getting hotter, and reduce the shrinkage, shrinkage, porosity, and shrinkage caused by uneven mold temperature. Casting defects such as porosity. Improve the appearance and internal quality of castings, the service life of molds and production efficiency. Achieving thermal equilibrium is the process of cooling the mold at high temperature and heating it at low temperature.

- (2) Control method—die-casting mold temperature controller;The mold temperature machine is divided into water type and oil type. The control temperature is about 160℃ and the water type is generally selected for higher environmental requirements, and the oil type is generally selected for higher than 160℃. The general main function of the mold temperature cnc machine is to use cold molds, and it is not enough to adjust and control the temperature in the die-casting production process.

- (3) Control mode—mold cooling unit;The mold cooling unit is used in conjunction with the mold’s own cooling circulating water to cool the high temperature parts of the mold to maintain the thermal balance of the mold cavity temperature.

5. Die-casting mold temperature monitoring method

- (1) Handheld thermal imaging camera;Conduct thermal imaging test every shift, and adjust the mold according to the temperature

- (2) Thermocouple or thermal imager temperature monitoring system.According to the mold situation, embed thermocouples in the mold (or place thermal imagers on the top and on the left and right sides of the mold), and monitor the mold temperature distribution in real time through the control system. Through the analysis of the monitoring data, the mold temperature can be adjusted to achieve the mold temperature. Temperature monitoring.

6、Comprehensive solution for die-casting mold temperature-Minghe

Link to this article:The importance and control principle of die casting mold temperature

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Mold Wiki,Thanks!^^