Molds, various molds and tools used in industrial production to obtain the required products by methods such as injection molding, blow molding, extrusion, die-casting or forging molding, smelting, and stamping. In short, a mold is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. Known as the “Mother of Industry”. Under the action of external force, the blank becomes a tool with a specific shape and size. It is widely used in punching, die forging, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, and compression molding or injection molding of engineering plastics, rubber, ceramics and other products.

Mold-Manufacturing

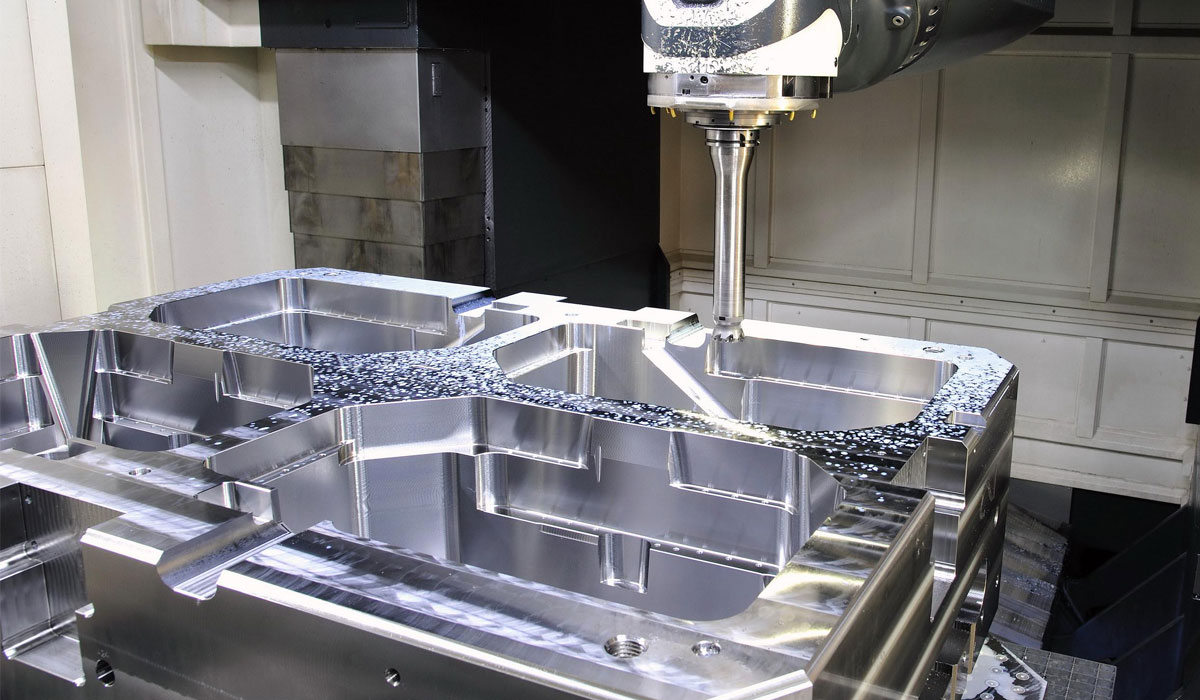

The mold has a specific contour or cavity shape, and the contour shape with a cutting edge can be used to separate the blank according to the contour shape (punching). The shape of the inner cavity can be used to obtain the corresponding three-dimensional shape of the blank. The mold generally includes two parts: a movable mold and a fixed mold (or a convex mold and a concave mold), which can be separated or combined. The parts are taken out when they are separated, and the blanks are injected into the mold cavity to form when they are closed. The mold is a precision tool with a complex shape and can withstand the expansion force of the blank. It has high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy. The development level of mold production is one of the important signs of the level of mechanical manufacturing.

The Species Of Mold Or Die

According to the processing object and processing technology, it can be divided into:

- Die for processing metal.

- Processing non-metal and powder metallurgy molds. Including plastic molds (such as two-color molds, compression molds and extrusion molds, etc.), rubber molds and powder metallurgy molds. According to the structural characteristics, the mold can be divided into a flat punching mold and a cavity mold with space. Molds are generally single-piece, small batch production.

The Classification Of Mold

According to the different molding materials

Hardware molds, plastic molds, and their special molds.

Hardware molds are divided into: including stamping molds (such as punching molds, bending molds, deep drawing molds, turning molds, shrinkage molds, undulating molds, bulging molds, plastic molds, etc.), forging molds (such as forging molds, upsetting molds, etc.) Forging dies, etc.), extrusion dies, extrusion dies, die-casting dies, forging dies, etc.;

Non-metallic molds are divided into: plastic molds, inorganic non-metallic molds, sand molds, vacuum molds, and paraffin wax molds.

Among them, with the rapid development of polymer plastics, plastic molds are closely related to people’s lives. Plastic molds can generally be divided into: injection molding molds, extrusion molding molds, gas-assisted molding molds, etc.

The Constitute Of Mold

In addition to the mold itself, it also needs a mold base, a mold base, and a mold core to cause the part ejection device. These parts are generally made of general-purpose type. Mold companies need to be bigger and more refined. They must determine product positioning and market positioning according to market demand, technology, capital, equipment and other conditions. These practices are especially worthy of learning and reference by small mold companies, and focus on gradually forming their own technical advantages and products. Advantage. Therefore, my country’s mold companies must actively strive to learn from the experience of these advanced foreign companies for better development in the future.

The Detail Material Of Mold

The most important factors of mold materials are thermal strength and thermal stability. Commonly used materials:

- mold materials: working temperature, forming materials, mold materials

- <300℃ zinc alloy Cr12, Cr12MoV, S-136, SLD, NAK80, GCr15, T8, T10.

- 300~500℃ aluminum alloy, copper alloy 5CrMnMo, 3Cr2W8, 9CrSi, W18Cr4V, 5CrNiMo, W6Mo5Cr4V2, M2.

- 500~800℃ Aluminum alloy, copper alloy, steel titanium GH130, GH33, GH37.

- 800~1000℃ Titanium alloy, steel, stainless steel, nickel alloy K3, K5, K17, K19, GH99, IN100, ЖC-6NX88, MAR-M200, TRW-NASA, WA.

- >1000℃ Nickel alloy, copper-based alloy mold, cemented carbide mold.

The Classification Of Gating System

According to different types of pouring system, plastic molds can be divided into three categories:

- (1) Large nozzle mold: The runner and gate are on the parting line, and they are demolded together with the product when the mold is opened. The design is the simplest, easy to process, and low cost, so more people use the large nozzle system to work. The plastic mold structure is divided into two parts: the movable mold and the fixed mold. The movable part of the injection machine is the movable mold (mostly the ejection side), and the injection end of the injection machine is generally inactive and called the fixed mold. Because the fixed mold part of the large nozzle mold is generally composed of two steel plates, this type of structural mold is also called a two-plate mold. The two-plate mold is the simplest structure in the large nozzle mold.

- (2) Fine nozzle mold: runners and gates are not on the parting line, generally directly on the product, so it is necessary to design an additional set of nozzle parting lines, the design is more complicated, and the processing is more difficult. Generally, the selection depends on the product requirements. Slim mouth system. The fixed part of the nozzle mold is generally composed of three steel plates, so this type of structural mold is also called the “three-plate mold”. The three-plate mold is the simplest structure in the nozzle mold.

- (3) Hot runner mold: The structure of this type of mold is roughly the same as that of the nozzle. The biggest difference is that the runner is in one or more hot runner plates and hot nozzles with constant temperature. There is no cold material demoulding, runner and pouring. The port is directly on the product, so the runner does not need to be demolded. This system is also called a nozzleless system, which can save raw materials, and is suitable for situations where raw materials are more expensive and products are demanding. It is difficult to design and process, and mold costs are high. The hot runner system, also known as the hot runner system, is mainly composed of a hot sprue sleeve, a hot runner plate, and a temperature control electric box. Our common hot runner system has two forms: single-point hot gate and multi-point hot gate. The single-point hot gate uses a single hot sprue sleeve to directly inject the molten plastic into the cavity. It is suitable for plastic molds with a single cavity and single gate; the multi-point hot gate branches the molten material to each The sub-heat sprue sleeve then enters the cavity. It is suitable for single-cavity multi-point feeding or multi-cavity molds.

Molding Classification

(1) Injection molding

The plastic is first added to the heating barrel of the injection machine. The plastic is heated and melted. Driven by the screw or plunger of the injection machine, it enters the mold cavity through the nozzle and the mold pouring system. It is hardened and shaped into injection molding due to physical and chemical effects. Products. Injection molding consists of a cycle consisting of injection, pressure holding (cooling) and demolding of plastic parts, so injection molding has periodic characteristics. The molding cycle of thermoplastic injection molding is short, the production efficiency is high, the wear of the melt on the mold is small, and the plastic parts with complex shapes, clear surface patterns and markings, and high dimensional accuracy can be molded in large quantities; but for plastics with large wall thickness changes It is difficult to avoid molding defects. The anisotropy of plastic parts is also one of the quality problems, and all possible measures should be adopted to minimize it.

(2) Compression molding

Commonly known as compression molding, it is one of the earliest methods of forming plastic parts. Compression molding is to add plastic directly into an open mold cavity with a certain temperature, and then close the mold. Under the action of heat and pressure, the plastic melts and becomes a fluid state. Due to physical and chemical effects, the plastic is hardened into a plastic part with a certain shape and size that remains unchanged at room temperature. Compression molding is mainly used for molding thermosetting plastics, such as phenolic molding powder, urea-formaldehyde and melamine-formaldehyde molding powder, glass fiber reinforced phenolic plastic, epoxy resin, DAP resin, silicone resin, polyimide and other molding materials. It can also process unsaturated polyester material (DMC), sheet molding compound (SMC), prefabricated integral molding compound (BMC), etc. In general, according to the matching structure of the upper and lower molds of the compression film, the compression molds are divided into three types: overflow type, non-flooding type, and semi-flooding type.

(3) Extrusion molding

It is a molding method in which the plastic in a viscous flow state passes through a die with a specific cross-sectional shape under a high temperature and a certain pressure, and then is shaped into a continuous profile with a desired cross-sectional shape at a lower temperature. The production process of extrusion molding includes preparation of molding materials, extrusion molding, cooling and shaping, traction and cutting, and post-processing of the extruded product (tempering or heat treatment). In the extrusion molding process, pay attention to adjusting the temperature of each heating section of the extruder barrel and the temperature of the die head, screw rotation, traction speed and other process parameters in order to obtain qualified extruded profiles. Special attention should be paid to adjusting the rate of polymer melt extruding from the die of the die. Because when the extrusion rate of the molten material is low, the extrudate has a smooth surface and uniform cross-sectional shape; but when the extrusion rate of the molten material reaches a certain limit, the surface of the extrudate will become rough and lose its luster , There are phenomena such as shark skin, orange peel, and shape distortion. When the extrusion rate is further increased, the surface of the extrudate is distorted, and even splits and breaks into melt fragments or cylinders. Therefore, the control of the extrusion rate is very important.

(4) Injection molding

Also known as die casting. It is to put the plastic raw materials into the preheated feeding chamber, then put the pressing column into the feeding chamber to lock the mold, apply pressure to the plastic through the pressing column, the plastic melts into a flowing state under high temperature and high pressure, and enters the cavity through the casting system Gradually solidify into plastic parts. This type of molding method is also called transfer molding. Injection molding is suitable for plastics that are lower than solid plastics. In principle, plastics that can be compression molded can also be molded by injection molding. But it is required that the molding material has good fluidity in the molten state when the temperature is lower than the solidification temperature, and has a larger solidification rate when the temperature is higher than the solidification temperature.

(5) Hollow molding

It is to fix the tube or sheet blank material made by extrusion or injection, which is still in the plasticized state, in the forming mold, and immediately pass in compressed air to force the blank material to expand and stick to the wall of the mold cavity. After cooling and shaping, it is demoulded, which is a processing method for obtaining the required hollow products. Plastics suitable for hollow molding are high-pressure polyethylene, low-pressure polyethylene, rigid polyvinyl chloride, soft polyvinyl chloride, polystyrene, polypropylene, polycarbonate, etc. According to the different molding methods of the parison, hollow molding is mainly divided into two types: extrusion blow molding and injection blow molding. The advantage of extrusion blow molding hollow molding is that the structure of the extruder and the extrusion blow molding die is simple, but the disadvantage is that the wall thickness of the parison is inconsistent, which easily causes the wall thickness of the plastic product to be uneven. The advantage of injection blow molding hollow molding is that the wall thickness of the parison is uniform and there is no flash. Because the injection parison has a bottom surface, the bottom of the hollow product will not produce seams, which is not only beautiful but also high in strength. The disadvantage is that the molding equipment and molds used are expensive, so this molding method is mostly used for mass production of small hollow products, and it is not widely used in extrusion blow molding.

(6) Die casting mould

Die casting mould is also called transfer mould. The plastic raw materials are added to the preheated feeding chamber, and then pressure is applied to the pressure column. The plastic is melted under high temperature and high pressure, and enters the cavity through the casting system of the mold, and gradually hardens into shape. This molding method is called die-casting. The mold used It is called a die-casting mold. This kind of mold is mostly used for the molding of thermoset plastics.

In addition, there are foam molding molds, glass fiber reinforced plastic low pressure molding molds, and so on.

Other Categories

(1) Hot runner mold

With the help of a heating device, the plastic in the pouring system will not solidify and will not be demolded with the product, so it is also called a runnerless mold. Advantages:

- 1) No waste

- 2) Can reduce the injection pressure, can use multi-cavity mold

- 3) Can shorten the molding cycle

- 4) Improve the quality of products Suitable for hot runner molding plastic characteristics:

- 5) Plastic melting temperature range is wider. At low temperature, it has good fluidity, and at high temperature, it has better thermal stability.

- 6) Sensitive to pressure, no flow without pressure, but can flow when pressure is applied.

- 7) Good specific heat, so as to cool down quickly in the mold.

The available hot runner plastics are PE, ABS, POM, PC, HIPS, PS. There are two commonly used hot runners: 1) heated runner mold 2) adiabatic runner mold.

(2) Hard mold

The steel plates used in the inner mold parts need to be heat treated after being purchased, such as quenching and carburizing, to meet the requirements of use. Such injection molds are called hard molds. For example, the inner mold parts are made of H13 steel, 420 steel, and S7 steel.

(3) Soft mold (below 44HRC)

The steel used in the inner mold part does not need to be heat treated after being purchased, and it can meet the requirements of use. Such injection molding is called soft mold. For example, the inner mold uses P20 steel, Ace steel, 420 steel, NAK80, aluminum, and beryllium copper.

The Principle Of Molding

Fundamental:

Two-shot molding mainly uses two-shot molding machine with two barrels and two sets of molds to form two-shot products in the order of two times.

Work steps:

- The raw material A is injected into the molding mold once through the A material tube to make a single-shot product A.

- After the cycle is opened, the product A is left in the male mold, and the forming motorized template is rotated to B to close the mold.

- Raw material B is injected into the B material tube twice to form a double-shot finished product, which is ejected from the mold.

Design Points

Review matters before design

- Mold material

- Molded product

- Molding machine selection

- Basic structure of mold base

Important items of mold design

1. Multi-color injection combination method

2. Runner system

- The injection pressure is low.

- Fast filling is completed, which can increase output.

- It can be injected uniformly and the product quality is better.

- Reduce waste and shorten injection time.

3. Forming equipment

- For the injection volume of each injection cylinder, determine which one to use for the color.

- The position and stroke of the striker.

- The configuration of the water circuit, oil circuit, and circuit on the rotating disk.

- The bearing weight of the rotating disk.

4. Mold base design: mold core configuration design

First, consider that the male side of the mold must be rotated 180 degrees, and the mold core must be arranged in cross-symmetrical arrangement, otherwise the mold cannot be closed for molding.

- Guide post: It has the function of guiding male and female molds. Concentricity must be maintained in multi-color molds.

- Return pin: Since the mold must rotate, the ejector plate must be fixed, and a spring is added to the return pin to keep the ejector plate stable.

- Positioning block: to ensure that the two mold bases are fixed to the large solid plate without deviation due to the gap of the screws.

- Adjustment block (wear-resistant block): It is mainly used for adjustment when the mold height z coordinate value is incorrect when the mold is closed.

- Ejection mechanism: The design of ejection method is the same as that of general molds.

- Cooling circuit design: The cooling circuit design of mold one and mold two should be the same as possible.