Aluminum-magnesium alloy die-casting mold temperature controllers are more different from die-casting products, and can also be divided into aluminum alloy die-casting mold temperature controllers and magnesium alloy die-casting mold temperature controllers. Choosing a suitable die-casting mold temperature controller can also effectively improve the dimensional accuracy of the die-casting machine.

The heating and cooling effect of the magnesium-aluminum alloy die-casting mold temperature controller can reduce the thermal stress of the mold, delay the generation of cracks on the mold surface, and extend the service life of the mold.

Before using the aluminum-magnesium die-casting mold temperature machine, check whether the cooling water is within the use standard to avoid damage to the die-casting mold temperature machine during use due to the lack of cooling water. Secondly, it is necessary to maintain a clean working environment to avoid dust; Use different heat transfer media to make different maintenance measures. The medium is water to keep clean, and the medium is oil to be replaced regularly; regularly check whether there is any leakage; regularly check the service life of parts and components, and perform regular replacement.

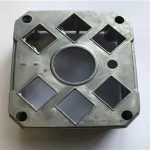

Die-casting mold temperature controller

Aluminum-magnesium alloy die-casting mold temperature controller use process:

- Turn on the aluminum-magnesium alloy die casting mold temperature controller according to the operating instructions of the host, and check the operation.

- Press the power switch first, then press the run stop button after the power is turned on

- After the run key is turned on, please adjust the temperature on the temperature control table to the temperature you want

- During the entire operation, the operator should always observe the operating conditions of the die-casting mold temperature controller, such as the operating sound, changes in the value of each parameter, etc., and make corresponding corrections according to the quality of the industry.

- Press the power switch in the last step, and then turn off the empty switch in the electric box

- Before the end of each shift, the die-casting mold temperature controller and peripheral equipment and the environment should be cleaned. At the same time, the mold surface should be cleaned, and the mold should be locked to leave a gap of 2CM between the movable and fixed molds before turning off the power.

- When handing over a shift, the operating status of the machine on the previous shift should be clearly stated and recorded, so as to facilitate the understanding of the equipment operating status and pending accidents in the next shift.

Link to this article:Instructions for using aluminum-magnesium alloy die-casting mold temperature controller

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Mold Wiki,Thanks!^^