The telescopic cone is a versatile tool widely utilized in various industries for shaping and forming materials. Its ability to extend and retract makes it particularly valuable in mold-making processes where precision and adaptability are crucial. This article explores the different types of molds where telescopic cones are employed, the benefits of using them, and the specific applications across various industries.

Definition and Overview

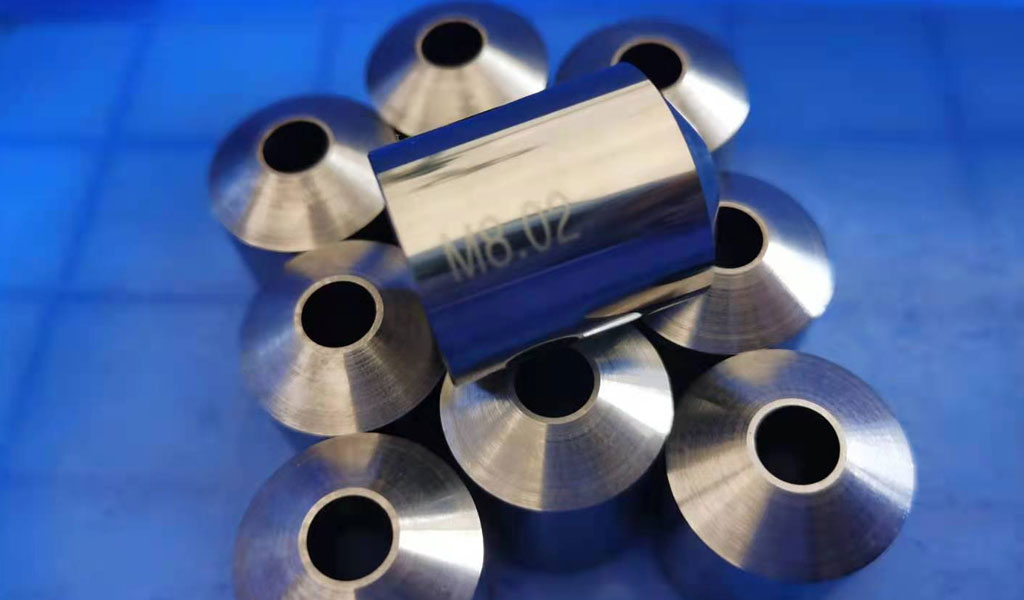

Telescopic Cone

A telescopic cone is a conical device capable of extending and contracting, typically used in processes where variable diameter and height are required. These cones can be made from various materials, including metal, plastic, and composite materials, depending on the application’s requirements.

Molding

Molding is a manufacturing process in which a material, often plastic or metal, is shaped into a desired form. The process involves pouring or injecting the material into a mold, where it cools and solidifies into the final product. Molds can be simple or complex, and they are used across a wide range of industries, including automotive, aerospace, consumer goods, and medical devices.

Types of Molds Utilizing Telescopic Cones

Injection Molds

Definition and Process

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. It is widely used for making plastic parts in high volumes.

Application of Telescopic Cones

Telescopic cones are used in injection molds to create hollow sections or intricate geometries that require a core that can be easily inserted and removed. This is particularly useful in producing items such as bottles, containers, and various automotive components.

Blow Molds

Definition and Process

Blow molding is a manufacturing process used to produce hollow plastic parts. The process involves inflating a heated plastic tube until it conforms to the shape of a mold.

Application of Telescopic Cones

In blow molding, telescopic cones can be used to form the necks of bottles and containers. Their adjustable nature allows for the production of different sizes and shapes without the need for multiple molds.

Compression Molds

Definition and Process

Compression molding involves placing a pre-measured amount of material into a heated mold and then applying pressure to form the part. It is commonly used for thermosetting plastics.

Application of Telescopic Cones

Telescopic cones in compression molds are often used to create parts with varying wall thicknesses or to form complex internal geometries. They are particularly useful in the automotive and aerospace industries for producing lightweight, high-strength components.

Extrusion Molds

Definition and Process

Extrusion molding is a process where material is forced through a die to create long shapes with a consistent cross-section. It is commonly used for producing pipes, tubing, and profiles.

Application of Telescopic Cones

Telescopic cones can be employed in extrusion molds to produce variable diameter sections of the extruded product. This is beneficial for applications where the product needs to fit into or connect with other parts of varying sizes.

Rotational Molds

Definition and Process

Rotational molding involves heating a hollow mold filled with material as it rotates, allowing the material to coat the interior surfaces of the mold evenly.

Application of Telescopic Cones

In rotational molding, telescopic cones can be used to create hollow parts with complex internal features. This method is particularly useful for producing large hollow items such as tanks, kayaks, and playground equipment.

Die Casting Molds

Definition and Process

Die casting is a metal casting process that involves forcing molten metal into a mold cavity under high pressure. It is commonly used for producing metal parts with intricate details.

Application of Telescopic Cones

Telescopic cones in die casting molds can be used to create complex internal geometries and to facilitate the removal of the cast part from the mold. This is particularly beneficial in the production of engine components, housings, and other high-precision metal parts.

Benefits of Using Telescopic Cones in Molds

Versatility

Telescopic cones offer significant versatility, allowing manufacturers to produce parts of varying sizes and shapes without needing multiple molds. This adaptability is crucial in industries where product designs frequently change.

Precision

The ability to extend and retract telescopic cones with precision enables the production of intricate and detailed parts. This precision is vital in industries such as aerospace and medical devices, where exact specifications are critical.

Cost-Effectiveness

Using telescopic cones can reduce manufacturing costs by eliminating the need for multiple molds. This reduction in tooling costs can be particularly beneficial for small to medium-sized production runs.

Improved Product Quality

Telescopic cones can enhance product quality by ensuring consistent wall thickness and reducing the likelihood of defects. This consistency is essential in applications where structural integrity and performance are paramount.

Industry-Specific Applications

Automotive Industry

In the automotive industry, telescopic cones are used in the production of various components, including engine parts, interior fittings, and body panels. Their ability to create complex geometries and maintain tight tolerances is crucial for ensuring the performance and safety of automotive parts.

Aerospace Industry

The aerospace industry benefits from the use of telescopic cones in the production of lightweight, high-strength components. These parts often have intricate internal structures that are essential for reducing weight while maintaining structural integrity.

Medical Device Manufacturing

In medical device manufacturing, precision and cleanliness are paramount. Telescopic cones are used to create complex and precise components, such as surgical instruments and implantable devices, where accuracy and biocompatibility are critical.

Consumer Goods

The production of consumer goods, including packaging, household items, and toys, often requires molds that can produce a wide variety of shapes and sizes. Telescopic cones provide the flexibility needed to meet these diverse requirements efficiently.

Packaging Industry

In the packaging industry, telescopic cones are used to produce containers, bottles, and other packaging materials with varying sizes and shapes. Their adaptability is crucial for accommodating different product requirements and branding needs.

Challenges and Considerations

Material Compatibility

One of the challenges in using telescopic cones is ensuring compatibility with the materials being molded. Different materials have varying properties, such as shrinkage rates and thermal expansion, which must be considered to ensure successful molding.

Maintenance and Durability

Telescopic cones must be durable and capable of withstanding the stresses of repeated use. Regular maintenance is essential to ensure their longevity and performance, particularly in high-volume production environments.

Design Complexity

Designing molds with telescopic cones can be more complex than traditional molds. The retractable nature of the cones requires precise engineering to ensure proper alignment and operation within the mold.

Future Developments

Advancements in Materials

The development of new materials with enhanced properties, such as higher strength and better thermal stability, will expand the applications of telescopic cones in molds. These advancements will enable the production of even more complex and high-performance parts.

Automation and Smart Manufacturing

The integration of automation and smart manufacturing technologies will further enhance the use of telescopic cones in molds. Automated systems can improve precision and efficiency, while smart technologies can provide real-time monitoring and feedback for optimized performance.

Sustainable Manufacturing

As industries move towards more sustainable manufacturing practices, the use of telescopic cones can contribute to reducing waste and improving resource efficiency. Their ability to produce parts with minimal material waste aligns with the goals of sustainable manufacturing.

Conclusion

Telescopic cones are a valuable tool in the field of 3d printing mold making, offering versatility, precision, and cost-effectiveness. Their applications span across various industries, from automotive and aerospace to medical devices and consumer goods. As technology and materials continue to advance, the use of telescopic cones in molds will likely expand, contributing to more efficient and sustainable manufacturing processes.

Link to this article:In Which Molds Can the Telescopic Cone Be Used?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Mold Wiki,Thanks!^^