After the processing of each part is completed, it can enter the final assembly stage. Due to the high precision of the mold parts and small errors, in addition to accurate positioning according to the time, the correct installation sequence must be arranged to ensure the normal operation of the stamping mold.

First, install the upper and lower die bases of the automobile stamping die, the upper die base is installed on the slider of the punch or press, and the lower die base is installed on the work surface of the punch or press. After the upper and lower mold bases are fixed, the mold parts can be installed on the mold base to ensure the correct and accurate installation position and avoid errors that may cause the mold to fail to work normally.

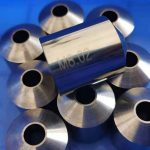

When installing the concave and convex molds, a uniform blanking gap should be left in between to ensure the quality of the stamping and prolong the service life of the stamping die. The assembly sequence of the upper and lower molds should be determined according to the mold structure, and different installation methods should be determined for the mold installation with and without guide pillars.

For complex installation, it is necessary to determine a reasonable assembly sequence according to the restrictions imposed on the installation of the upper and lower mold parts. Sometimes improper installation sequence not only affects the subsequent installation work, but also may not install, so the correct installation sequence is very important

Link to this article:How long is the service life of automobile stamping dies?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Mold Wiki,Thanks!^^