On September 28, the 2016 National Key R&D Project “Key Technologies for Manufacturing Large-size High-Performance Magnesium Alloy Deformed Processing Materials” was officially launched at Chongqing University. The project was led by Chongqing University, with the Institute of Metal Research, Chinese Academy of Sciences, Shanghai Jiaotong University, and Chongqing. 21 units including Changan Automobile Co., Ltd. jointly undertake it.

The high performance, large size and low cost of wrought magnesium alloys (referred to as “three modernizations”) are the keys to their large-scale promotion and application and the healthy development of the entire magnesium industry. Therefore, solving the current bottleneck problems of key technologies such as high-performance wrought magnesium alloys and their processing and manufacturing is of great strategic significance for the large-scale promotion of the application of magnesium alloy products and even the enhancement of the competitiveness of the magnesium alloy industry.

China has 70% of the world’s magnesium resources. Chongqing is an important production base for cast magnesium alloy products, but there are relatively few applications of wrought magnesium alloys with great prospects. To this end, the start of the project will focus on high performance, large specifications and low cost, and on the basis of “high alloy, high purity and high homogeneity”, the large-scale production and product diversity of Chongqing magnesium alloy deformed materials will be carried out. Tackling common key technologies.

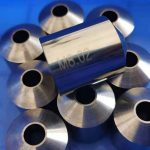

The project leader, Professor Pan Fusheng, told reporters that this project will solve a series of common key technical problems in the industrialization of China’s ultra-high-strength/large-size magnesium alloy deformed materials, such as poor performance, difficult forming, low efficiency, high cost, and narrow application fields. Further solve the urgent needs of major industries and major projects for large-scale high-performance machining magnesium alloy deformable materials. At the same time, the project will also develop a batch of high-performance deformed magnesium alloys to form 5 key technologies and equipment for the preparation and processing of large-size high-performance magnesium alloy deformed materials such as high-strength and tough profiles and forgings, high-precision plate and strip coils, and large-size Two application technologies for residual stress reduction and surface protection of deformed materials.

It is reported that the results of these projects will eventually be able to achieve integrated application demonstrations of magnesium alloys in key industries and major projects such as transportation, electronic communications, aerospace, weaponry and equipment. At the same time, after the completion of the project, the application of wrought magnesium alloy products in China is expected to increase by more than 5-10 times within 5-10 years. The benefits of energy saving and emission reduction are significant, and the social and economic benefits are huge. Will be of great significance.

Link to this article:Chongqing will become a world-class deep processing base for wrought magnesium alloys

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Mold Wiki,Thanks!^^