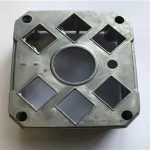

- die casting mold design, the three-dimensional appearance of aluminum alloy die-casting mold products, the plane is more than regular, for the novice mold designer, the mold design can be done;

- The structure of the back mold side of the die-casting mold drawing product will have convex features, and the parting surface can be directly split by coordinates;

- Die-casting mold design-draft detection, with plus or minus 0.5 as the analysis value, which meets the mold opening requirements;

- Die-casting mold drawing-internal thickness analysis, there are assembly structure holes at both ends, and its structure is thicker, and there are screw holes for assembly;

- Die-casting mold drawings, the overall structure of the mold’s appearance, the die-casting mold does not have an I-plate, and the mold slot must be opened;

- die casting molding drawings, the sliding block position structure section line, the shovel base is left in its original form, and the inclined guide pillar is as good as possible to 16;

- Die-casting mold drawings, cross-sectional view of the split cone, on the whole, the structure of the die-casting mold is relatively simple, and the flow channel of the split cone is not well designed;

- Die-casting mold design tutorial, the front mold core plane has raised steps, and the opposite side of the runner is the slag bag. The parting surface can be designed once with the UG split body. The slag bag needs to be stretched, drafted, and chamfered. ;

- Die-casting mold design, post-mold structure design, and general die-casting mold design, all need to run with mold flow analysis software, and then draw the glue runner, which is a major difficulty in die-casting mold design;

- Die-casting mold design, the original structure design of the slide block, the side hole is cored by the slide block, and the double screws are fixed on the row seat.

Link to this article: Analysis of the structure of aluminum alloy die-casting die for heat sink

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:Mold Wiki,Thanks!^^